Advantage:

● High Efficiency: Capable of achieving 16/24 cavities

● Short Cycle Time:13~16s

● Multifunctional: Operates as both an injection blow molding and standard injection molding machine.

Application:

● LED light bulb: LED PP PC diffuser, housing, cover and lampshades.

● Energy-saving lamp manufacturing: produce lampshades for energy-saving lamps.

● Toy manufacturing: produce various spherical toys.

● Packaging industry: manufacture various spherical packaging products, such as plastic spherical bottle, containers, etc.

● Auto parts manufacturing: produce spherical or spherical parts, such as spherical connectors and switch buttons, etc.

Advantage:

● 420T can produce up to 25L bucket with lML(in-mold labeling) system

● 1000T machine can achieve 2 cavities

● High Speed: 200mm/s

● Big Opening Stroke: 1300mm

Application:

● Production of packaging and chemical raw materials, pesticides, fertilizers, etc.

● Production of packaging and transporting waterproof coatings, paints, etc.

● Production of pesticide and agricultural chemical buckets.

● Production of engine oil buckets for packaging and transporting engine oil, lubricants, etc.

● Production of antifreeze buckets for packaging and transporting antifreeze.

● Production of latex buckets for packaging and transporting latex.

● Production of enzyme drums for packaging and transporting enzymes, etc.

Advantage:

● New Structure: Mechanical parts? Zero wear!

● High Speed: 200mm/s

● Maintenance-Free for Two Decades! !

● Electric Pre-plasticization (Alternative)

Application:

● Food and beverage packaging: used to produce PET preforms which can be further processed into various beverage bottles, edible oil bottles, etc.

● Daily chemical products: can manufacture preforms of cosmetics bottles, shampoo bottles, shower gel bottles, etc.

● Pharmaceutical packaging: production of medicine bottle preforms, ensuring the sealing and safety of pharmaceutical packaging.

● Industrial container packaging: manufacturing various industrial bottle preforms, such as chemical reagent bottles, lubricating oil bottles, etc.

Advantage:

● Wide tie bar spacing and long opening stroke--suitable for manufacturing large or deep products.

● Balanced clamping cylinders--minimizes product shrinkage or deformation.

Application:

● Automotive industry:bumpers, dashboards, door panels, central control panels.

● Home appliance industry: washer drums, home appliance industry, refrigerator shells, air conditioner shells.

● Logistics industry: large pallets, logistics turnover boxes.

● Building materials industry: manhole covers.

● Packaging industry: large plastic drums, large cardboard boxes.

● Aerospace industry: aircraft interior parts, aerospace equipment shells.

● Other industries: large amusement facility parts, medical equipment shells.

Advantage:

● Servo rotary table

● Fast and accurate

● Larger space for molds

● 2/3/4 colors/materials (Alternative)

Application:

● Automotive industry:interior panel, central control panel, door trim panels, seat parts, seat parts, bumpers, wheel arch cover.

● Electronic products industry: mobile phone cases, laptop cases, tablet protective covers, game console handles.

● Toy industry: doll toys, building block toys, plush toy plastic accessories, toy cars.

● Home appliance industry: electric kettle shells, hair dryer shells, electric toothbrush shells, TV orders, refrigerator door handles, washing machine control panels

● Daily necessities industry: cosmetic packaging bottles, food packaging boxes, tableware, trash bins, storage boxes, coat racks.

Advantage:

● Electric pre-plasticization (Alternative).

● Energy-saving and power-efficient.

● Mechanical parts? Zero wear!

Application:

● Degradable thin-walled food boxes: our injection molding machine can precisely control the wall thickness, making it lightweight and to carry, and it can decompose in appropriate composting facilities after use.

● Small thin-walled containers: such as cosmetics sample bottles,etc.

● Degradable thin-walled food packaging containers/takeout food packaging: such as yogurt cups, pudding cups, etc. Our injection molding machine can precisely control the wall thickness of the container, making the product lightweight while ensuring the packaging quality of the food.

ABOUT US

INFORMATION ABOUT US

ZHENHUA PLASTIC MACHINERY (DONGGUAN) CO., LTD

ZHENHUA is an integrated company engaged in injection molding machine maintenance, design and development, manufacturing, sales, and after-sales service for more than 30 years.

ZHENHUA provides customers with personalized high-quality machinery based on the injection molding design principle of “thin wall high pressure”. Each machine achieves standardization of accessories, universal, easy procurement, and easy maintenance, so that customers can improve production efficiency and reduce use costs.

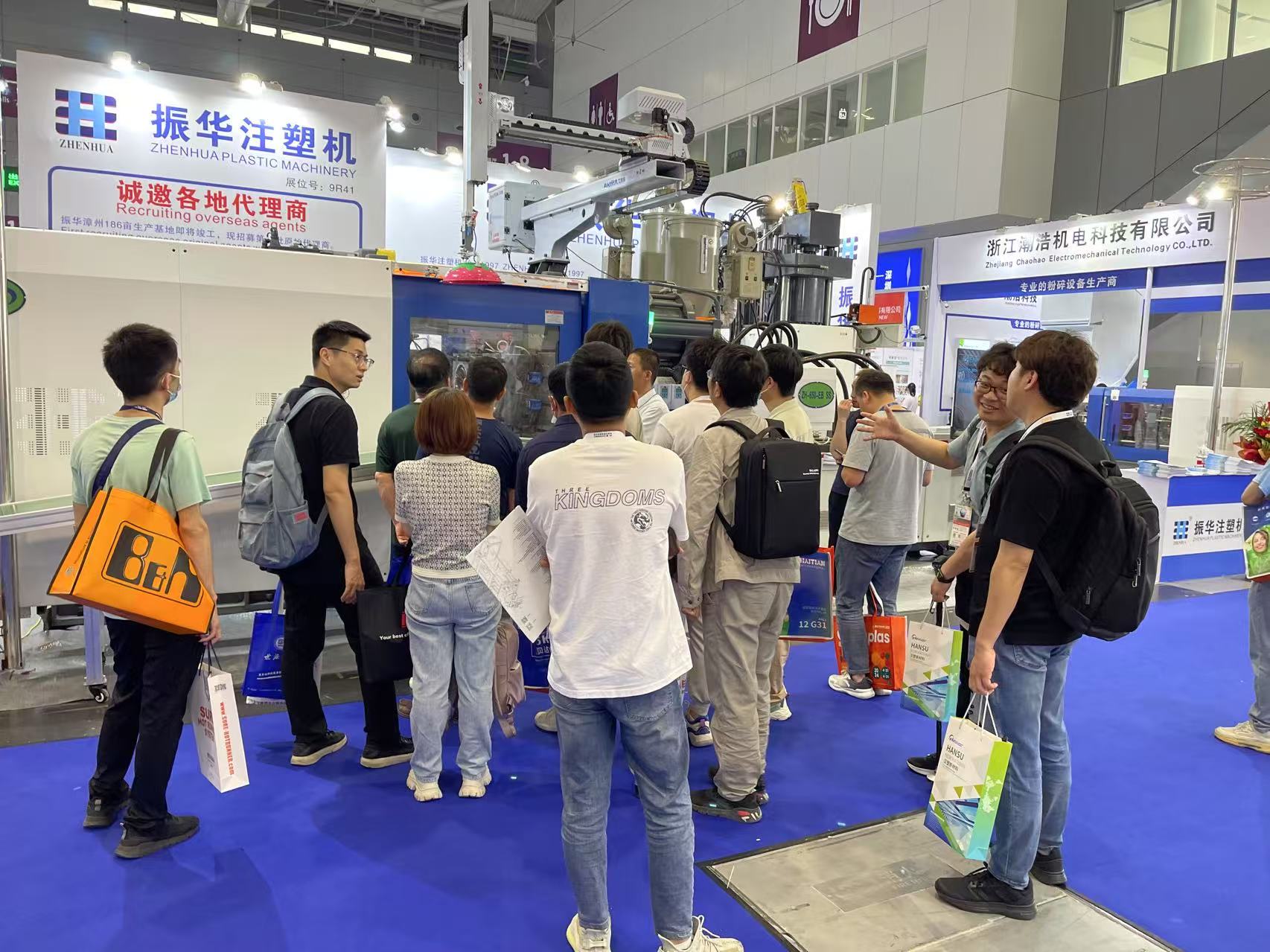

OUR EXHIBITION

01

In temms of exhibitors, companies from dozens of countries and regions around the world actively participate, bringing diverse technological concepts and innovative products.

02

As an injection molding machine manufacturer, we can showcase the latest products and technologies to our customers by attending the exhibition. We can also provide them with detailed information and customized solutions.

This allows buyers to make informed decisions and establish direct contact with us for potential collaborations.

Do you have any demand for high-efficiency machines?

Contact us now!

HOT PRODUCTS

- Vertical IMM with 3 Stations Rotary Table for LED Bulb Housing

- Hybrid Injection Molding Machine for Thin-walled Disposable Bowl Producing

- 650T Two Plates/Double platen IMM For Chair Producing

- 120T LSR Injection Molding Machine for Silicone Pacifier Producing

- Two Colors/Components Injection Molding Machine

- All-electric Injection Molding Machine for Plastic Hand Fan Making

- Injection Molding Machine for Building Block Base Plate Producing

- 268T Injection Molding Machine for LED PBT Housing Producing

- Injection Molding Machine Production of Artificial Flower

Quick Navigation

Our Advantage

With more than 30 years of experience in maintenance and manufacturing, ZHENHUA provides customers with personalized high-quality machinery based on the injection molding design principle of “thin wall high pressure".

Each machine achieves standardization of accessories, universal, easy procurement, and easy maintenance, so that customers can improve production efficiency and reduce use costs.

More than 30 years experiences in injection molding machine.

Solved countless production problems for customers.

Help customer improved about 20% efficiency in production.

Keep Update With

Our Company News

How To Select Injection Molding Machine2025-03-11Injection molding machines have become an integral part of manufacturing. These machines play a vital role in the production process, from producing small plastic parts to large automotive components. However, selecting the right injection molding machine for your specif...

How To Select Injection Molding Machine2025-03-11Injection molding machines have become an integral part of manufacturing. These machines play a vital role in the production process, from producing small plastic parts to large automotive components. However, selecting the right injection molding machine for your specif... We usually divide injection molding machines into the following categories:2025-03-111. According to the driving mode: Hydraulic Injection Molding Machine All Electric Injection Molding Machine Hybrid Electric Injection Molding Machine At present, most of factories use oil-electric hybrid injection m...

We usually divide injection molding machines into the following categories:2025-03-111. According to the driving mode: Hydraulic Injection Molding Machine All Electric Injection Molding Machine Hybrid Electric Injection Molding Machine At present, most of factories use oil-electric hybrid injection m... Which machine is used to make syringe producing?2025-03-11In the manufacturing industry, precision and efficiency are of vital importance, especially when producing medical devices such as syringes. The process of manufacturing these essential tools relies heavily on advanced technology, and one of the most efficient methods is...

Which machine is used to make syringe producing?2025-03-11In the manufacturing industry, precision and efficiency are of vital importance, especially when producing medical devices such as syringes. The process of manufacturing these essential tools relies heavily on advanced technology, and one of the most efficient methods is...

Leave A Message

By clicking 'Allow All', you agree to the storage of cookies on your device to enhance site navigation, analyze site usage and assist with our marketing efforts.